Understanding the intricate chemical composition of stainless steels is pivotal in comprehending their diverse applications across industries. Stainless steels are classified into various categories based on their composition, each designed to exhibit unique properties and performance under different conditions. In this comprehensive exploration, we delve into the chemical compositions of austenitic, martensitic, ferritic, and duplex stainless steels as per GB/T 3098.6, GB/T 3098.15, GB/T 3098.16, and GB/T 3098.21 standards. Additionally, we uncover the specific chemical compositions characterizing high-temperature stainless steels and nickel alloys, shedding light on their distinct attributes and utility in demanding environments.

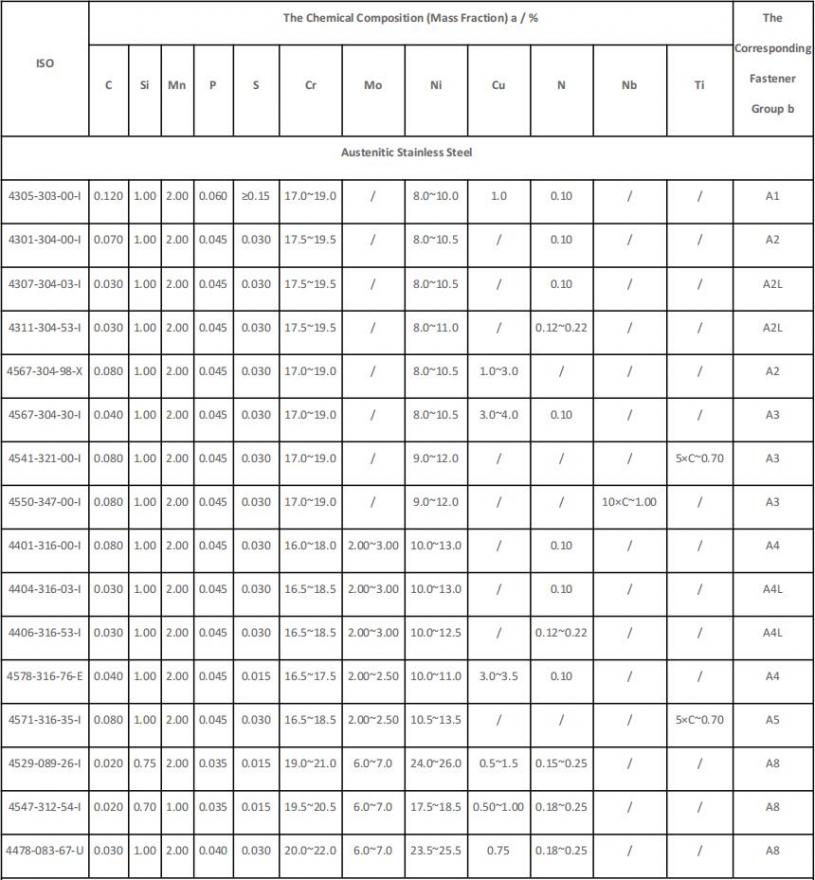

Table 1 Chemical Composition of Austenitic Stainless Steel

(GB/T 3098.6, GB/T 3098.15, GB/T 3098.16, GB/T 3098.21)

Note: Except where ranges or minimum values are specified, all listed components in the table are maximum values.

Note: Except where ranges or minimum values are specified, all listed components in the table are maximum values.

a. Elements not quoted in this table shall not be intentionally added to the steel without the agreement of the purchaser, other than for the purpose of finishing the heat. All reasonable precautions shall be taken to prevent the addition, from scrap or other material used in manufacture, of such elements which affect the hardenability, mechanical properties and applicability.

b. The steel group corresponds closely to the composition range specified in GB/T 3098.6 and GB/T 3098.15, but the constituents included in this table may not necessarily align completely.

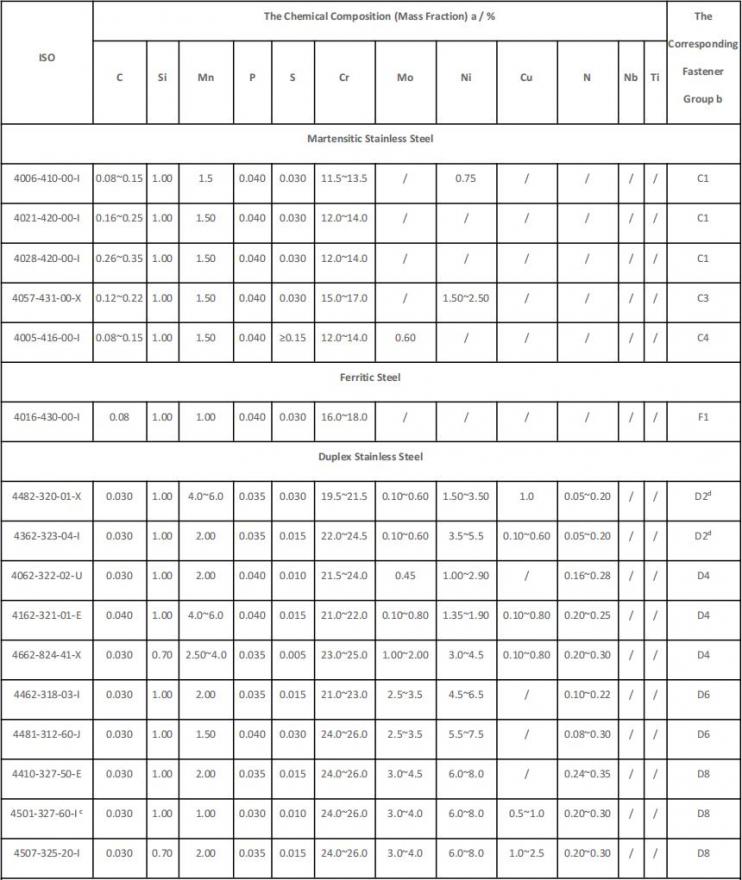

Table 2 Chemical Composition of Martensitic, Ferritic, and Duplex Stainless Steels

(GB/T 3098.6, GB/T 3098.15, GB/T 3098.16, GB/T 3098.21)

Note: Except where ranges or minimum values are specified, all listed components in the table are maximum values

Note: Except where ranges or minimum values are specified, all listed components in the table are maximum values

a. Elements not quoted in this table shall not be intentionally added to the steel without the agreement of the purchaser, other than for the purpose of finishing the heat. All reasonable precautions shall be taken to prevent the addition, from scrap or other material used in manufacture, of such elements which affect the hardenability, mechanical properties and applicability.

b. The steel group closely aligns with the composition range specified in GB/T 3098.6 and GB/T 3098.15; however, the constituents included in this table may not necessarily match completely.

c. The tungsten content should be between 0.5% and 1.0%.

d. When wCr + 3.3wMo + 16wN > 24 and meets the standards of GB/T 3098 stainless steel series, it can be recognized as D4

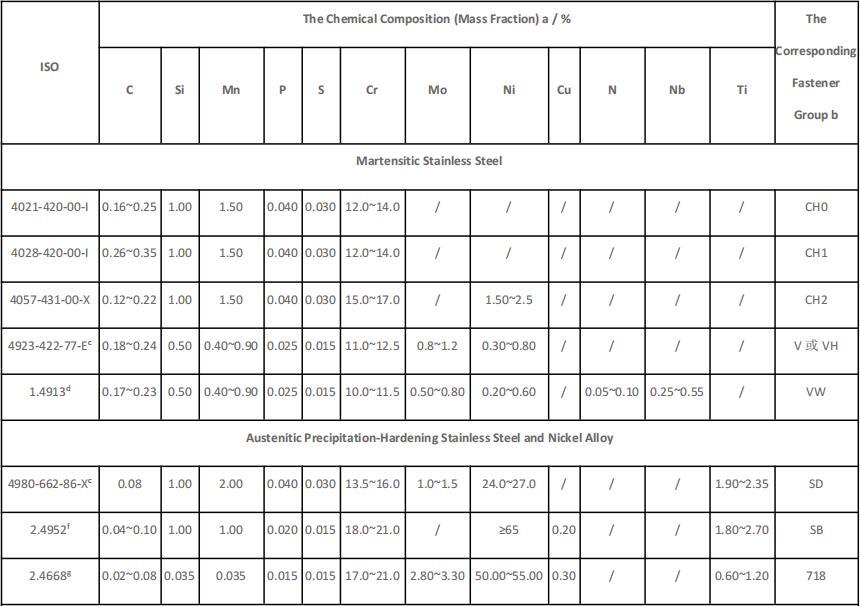

Table 3 Chemical Composition of High-Temperature Stainless Steels and Nickel Alloys

(GB/T 3098.6, GB/T 3098.15, GB/T 3098.16, GB/T 3098.21)

Note: All listed components in the table are maximum values unless specified as a range or minimum value.

a. Elements not quoted in this table shall not be intentionally added to the steel without the agreement of the purchaser, other than for the purpose of finishing the heat. All reasonable precautions shall be taken to prevent the addition, from scrap or other material used in manufacture, of such elements which affect the hardenability, mechanical properties and applicability.

b. The steel group closely aligns with the composition range specified in GB/T 3098.6 and GB/T 3098.15; however, the constituents included in this table may not necessarily match completely.

c. In addition, vanadium content shall be 0.25% to 0.35%.

d. Chemical composition in accordance with EN 10269; in addition, aluminium content shall ≤0.020%, vanadium shall be 0.10% to 0.30%, boron ≤0.0015%.

e. In addition, aluminium content shall ≤0.35%, vanadium shall be 0.10% to 0.50%, vanadium shall be 0.001% to 0.010%.

f. Chemical composition in accordance with EN 10269; in addition, aluminium content shall be 1.00% to 1.80%, cobalt ≤1.00%, steel ≤1.50%, boron ≤0.008%.

g. Chemical composition in accordance with EN 10269; in addition, aluminium content shall be 0.30% to 0.70%, cobalt ≤1.00%, vanadium shall be 0.002% to 0.006%, niobium shall be 4.7% to 5.50%(iron: balance).