Introduction

ASME B18.6.3-2013 "Machine Screws Tapping Screws, and Metallic Drive Screws(Inch Series)" is a national standard for machine screw products in the United States. This standard outlines the requirements for various head types of machine screws such as slotted, cross-recessed, square-slotted, and plum-shaped slots. General requirements, dimensions, and measurements for specific locations. While the standard's data is extensively explained on the website, specific product requirements lack detailed descriptions. Below is a overview of the general requirements for machine screws as per the standard for reference. If there are any discrepancies between the descriptions provided here and the original document, the content of the original document should be considered authoritative.

1 Machine Screw Threads

Uncoated Threads. Unless otherwise specified, threads for sizes No. 0 through 3/4 in shall conform to the requirements of Class 2A according to ASME B1.1 Threads for sizes No.0000, No.000, and No.00 shall conform to the requirements in Mandatory Appendix V.

Coated or Plated Threads. Unless otherwise specified, coated or plated threads shall be accepted based on the high limits of Class 3A (GO) and the low limits of Class 2A (NO GO).

Thread Acceptance. Thread acceptance shall be determined using System 21 in ASME B1.3.

2 Machine Screw Length of Thread

Machine screws shall have thread lengths conforming to the following (on screws threaded full length, the distance to the first full-form thread shall be measured, parallel to the axis of screw, from the bearing surface of the head to the face of a nonchamfered or noncounterbored special 3A GO thread ring gage assembled by hand as far as the thread will permit):

(a) Sizes No. 5 and Smaller. Screws of nominal lengths equal to three diameters and shorter shall have full-form threads extending to within one pitch (thread) of the bearing surface of the head, or closer, if practicable. Nominal lengths greater than three diameters, up to and including 11/8 in., shall have full-form threads extending to within two pitches (threads) of the bearing surface of the head, or closer, if practicable. Screws of longer nominal lengths shall, unless otherwise specified, have a minimum length of full-form thread of 1 in.

(b) Sizes No. 6 and Larger. Screws of nominal lengths equal to three diameters and shorter shall have full-form threads extending to within one pitch (thread) of the bearing surface of the head, or closer, if practicable. Nominal lengths greater than three diameters, up to and including 2 in., shall have full-form threads extending to within two pitches (threads) of the bearing surface of the head, or closer, if practicable. Screws of longer nominal lengths shall have a minimum length of full-form thread of 1.50 in. unless otherwise specified.

3 Machine Screw Length Measurement

The nominal length of screw, L, shall be measured, parallel to the axis of screw, from the extreme point to the plane of the bearing surface for screws having perpendicular bearing surface type heads, and to the theoretical intersection of the top surface of head with the head diameter for screws having countersunk type heads. For all oval heads, the overall length, L0, shall be measured, parallel to the axis of the screw, from the extreme point to the top of the head, where

L0(overall length) = L (nominal length) + C (head crown height)

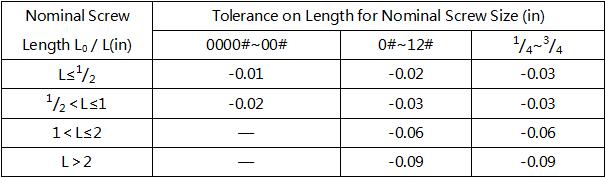

4 Machine Screw Tolerance on Length

The length tolerance shall apply to L0 for all oval heads and to L for all other head styles. The tolerance on the length of machine screws shall conform to the following for the respective screw types:

NOTE: Machine screws can be made to any length, but they are generally produced in fractional length increments of 1/16 in. for screws up to 5/8 in. Long, 1/8 in. for screws over 5/8 in. through 11/2 in. Long, and 1/4 in. for screws over 11/2 in. Long.

5 Machine Screw Diameter of Body

The diameter of body on machine screws having other than trim heads shall not be less than the Class 2A thread minimum pitch diameter nor greater than the basic major diameter of the thread.

NOTE: Trim head screws not threaded to the head shall have a shoulder of 0.062 in. min length under the head with diameter limits as specified in the dimensional tables.

6 Machine Screw Points

Unless otherwise specified, machine screws shall have plain sheared ends. When chamfered points are specified by the purchaser, the point diameter shall be slightly under the minimum minor diameter and the chamfer length shall be one to two thread pitches in length.

7 Machine Screw Straightness

Straightness shall be determined using the gaging practices in B18.29. For lengths 12 in. and shorter, the tolerance shall be 0.006 in. per inch, and for lengths 24 in. and shorter but greater than 12 in., the tolerance shall be 0.008 in. per inch. For information of a typical gage design and an inspection procedure, consult ASME B18.2.9.

8 Machine Screw Material

Carbon Steel - Unhardened. Unless otherwise specified, machine screws shall be non-heat-treated low carbon steel, such as 1006 through 1022, with a hardness of Rockwell B69-100.

Carbon Steel - Hardened. When hardened machine screws are specified, they shall be made from low or medium carbon steel, such as 1018 through 1038, with or without boron, through-hardened to Rockwell C25-38.

Stainless Steel. When specified, stainless steel screws shall comply with the chemical requirements of ASTM F837.

Nonferrous. When specified, nonferrous screws shall comply with the chemical requirements of ASTM F468.

9 Machine Screw Finish

Unless otherwise specified, screws shall be supplied with a natural (as processed) finish, unplated or uncoated. When plating is specified, it shall conform to the requirements of ASTM F1941. When other coatings are specified, the requirements shall be agreed upon by the supplier and the purchaser.

10 Machine Screw Workmanship

Screws shall not contain an excess of surface imperfections that may affect their serviceability, such as burrs, seams, laps, loose scale, and other irregularities.

11 Machine Screw Designation

Machine screws shall be designated by the following data, preferably in the sequence shown:

(1) product name, including head type and driving provision and designation of the standard

(2) nominal size (number, fraction, or decimal equivalent)

(3) threads per inch

(4) nominal length (fraction or decimal equivalent)

(5) header point, if desired

(6) material

(7) protective coating, if required

EXAMPLES:

(1) Slotted pan head machine screws, ASME B18.6.3, 1/4 - 20 × 11/4, hardened carbon steel, zinc plated per ASTM F1941 Fe/Zn 3A.

(2) Type IA cross recessed fillister head machine screw, ASME B18.6.3, 6 - 32 × 3/4, UNS C46200 brass per ASTM F468.

(3) Hexagon washer head machine screw, ASME B18.6.3, 0.375 - 16 × 1.50, unhardened carbon steel.

(4) Type I cross recessed flat countersunk head machine screw, ASME B18.6.3, 0.190 - 24 × 1.50, unhardened carbon steel, phosphate/oil per ASTM E1137 Grade 0D.